Classification Of Materials

ABC Classification

Stockroom inventory is classified into categories called ABC.

* "A" - items are the highest priority, the tightest control, frequent deliveries, close follow-up, and accurate records. Planning and Scheduling these parts utilize MRP (Material Requirements Planning), DRP (Distribution Requirements Planning, or EOQ (Economic Order Quantity) or other lot sizing techniques such as Lot for Lot. 10 % of the "A" items volume accounts for 70% of the total inventory value

* "B" - items are the priority when low or out of stock. Normal control is used and good records are maintained. EOQ and other lot sizing methods can be used effectively with these items. "B" items account for 20% of the total inventory value, and 20% of the inventory volume.

* "C" - items are the lowest priority, simplest method of control. Min/Max used for ordering. These parts are usually expensed, as there are no records for them.

These parts represent 10% of the total value, and 70% of the volume.

Managing Inventories by ABC:

ABC analysis is the method of classifying items involved in a decision situation on the basis of their relative importance. Its classification may be on the basis of monetary value, availability of resources, variations in lead-time, part criticality to the running of a facility, new customer partsunique to that product, and others.

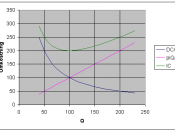

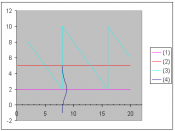

Management needs to look at a descending dollar and volume chart in order to make decisionson ABC analysis. Once the top dollar items of usage are identified, and its corresponding volume.

Parts can be coded by the proper classification. Through this report ABC analysis can begin and recommended lists on stock codes, inventory levels to maintain, obsolescence recommendations, and discontinued items can be determined. A typical ABC analysis is shown in the following example:

From this example (KT Tire is a fictitious company, but the data is actual data derived from a client company),

"A" items represent 70% of the dollars and 8.61 % of the total volume of parts.

"B" items represent 20% of the dollars and 21.09% of the total parts.

"C" items represent 10%of the total dollars and 70.3% of the total part volume.

Cycle inventory can be managed through ABC analysis.

Once ABC items are coded in the file maintenance system, they are sorted by the ABC code. The CMMS randomly selects "A" items so that all can be processed typically in a two-month period, "B" items typically can all be processed in a six-month period, and "C" items can all be processed in a year period. The daily count would reflect this percentage of parts. For example, if a storeroom has 2000 parts in storage (Breakdown would be 100 "A" items counted monthly, 66 "B" items monthly, and 125 "C" items counted monthly), a typical daily selection to be counted would be 5 "A" items, 4 "B"items, and 7 "C" items, or a total of 16 items each day. When the computer count and the actual count disagree, a specific dollar value of tolerance is determined, before a decision is made for a second count. If, after the second count, there still is a discrepancy beyond the acceptable tolerance, a third count occurs. ABC management then also takes place in the investigation of the discrepancies.

"A" items, being the most valued, take the longest to investigate, with "B" second, and "C" last.

Once the investigation concludes, the inventory is adjusted. Management must sign off on the adjustment.

Other uses of ABC are in the management of storage areas by the storeroom manager.

"A" items must be watched and reviewed more closely due to its dollar value and importance to the facility.

Normally,

"A" items are stored at the lower levels of the bin.

"B" items are stored in the mid levels and are normally replacement parts that may not have the criticality or dollar value of the "A" items.

"C" items are stored in all other areas.

Insurance spares may be considered "A" items, since they are extremely critical to the running of the plant. Critical components to insurance spares may also be considered "A" items if a plant shutdown could occur if the part was not in storage. All other replacement parts can be classified within the ABC coding.

Obsolescence budgeting also takes the management of ABC analysis into consideration.

"A"items have the most impact on the budget, if it is determined to be obsolete and scrapped from inventory. These parts may fool the reviewer because the "A" parts may not have a use for several years, but due to its critical importance may be needed at a later date. The slow moving activity report would not detect this need. Management and storeroom management need to consider all aspects of the parts before it is scrapped to obsolescence. ABC analysis puts a perspective that enhances this decision-making.

Other use of ABC analysis is in the reorganization of the storeroom.

Yearly, a review of parts storage areas needs to take place by the storeroom manager. In this analysis, ABC coding should be considered so that the "A" parts are continually being moved to the lower or easier access areas. 'B" items are to be moved to middle areas, and "C" items placed in all other areas of the stores.

ABC analysis even affects lot-sizing considerations.

A plant using EOQ (Economic Order Quantity where a fixed order quantity is established that minimizes the total of carrying and preparation costs under conditions of certainty and independent demand.) uses ABC as well, so that inventory levels are minimized with the higher cost part.

A review of the ABC Codes for the parts in stores should occur quarterly. Improper coding of parts may result in incomplete investigations of more expensive parts, improper storage, poor decisions on obsolescence and scrap, and less than adequate lot sizing.

ABC Code Management is an important tool for parts in storage. It puts a perspective on parts and emphasizes its value in relation to the quantity on-hand. Without this type of inventory management program in use, inventory decision-making would be based on just quantity alone.

ABC management techniques methods involve both quantity and inventory valuation to make a more complete evaluation of parts in storage.

Other Classifications:

VED Classification

Certain materials are important by their absence and not necessarily by their presence. If they are not available they hold up production and therefore there are high costs of shutdown. By themselves these materials may not be priced high in the market. These are critical items required in adequate quantity.

V- Vital - Most Critical

E- Essential

D- Desirable - Not Critical

Combined ABC-VED Analysis

We may Classify the inventory into 9 categories

for management control purposes, instead of only 3 categories in ABC or VED analysis.

Classification Based on Shelf Life

* Low Shelf life

* Medium Shelf life

* Long Shelf life

This classification is particularly important in Chemical and Pharma industry which have a low shelf-life.

Classification Based on Size

* Bulky

* Medium Bulky

* Not Bulky

This classification gains importance in terms of providing space for the materials in the stores .

Classification based on Rate of Movement of Materials

* Fast Moving

* Slow Moving

* Non-Moving

This classification gains importance in terms of rate of movement of materials in the stores .

Non moving items are the items which has become obsolete over time.

Conclusion

The idea behind these classifications is to draw the attention of the management selectively. The problem-materials are thus highlighted and precious management time can be devoted to these problem items in the inventory.

Management by exception for better control is the theme behind these Classifications.