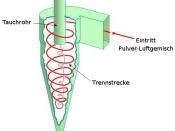

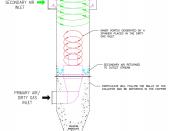

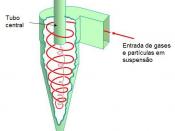

I.INTRODUCTIONCyclone is a piece of equipment consisting of a vertical cylinder with a conical bottom with a tangential inlet near the top, and an outlet for removal of the separated fraction at the bottom of the cone (Mc Cabe et al, 1985 ). It utilizes centrifugal forces and low pressure caused by spinning motion to separate materials of differing density, size, and shape. It is a very useful piece of equipment for the removal from air streams of particles above 10 micrometer in diameter. The equipment is a settling chamber so arranged that the particle laden air spirals round the cylinder to create centrifugal forces which are created by the spinning stream. According to Perry and Chilton (1973), the centrifugal separating force or acceleration may range from five times gravity in very large diameter, low resistance cyclones to 2500 times gravity in very small, high resistance units. This forces heavier particles to the outer edges, while lighter particles remain in the carrier material.

The heavier particles are removed from the separator via the lower opening. Lighter particles along with the carrier medium exit through the vortex finder located at the top of the separator.

Hydrocyclones or hydroclones are cyclone separators for solid-liquid separation. They are used either as thickeners or classifiers.

Cyclones are very popular because there are no moving parts that can wear out or break. With no moving parts involved and mainly consisting of a drum with a funnel on the bottom and inlet and exit ports, a cyclone separator is fairly simple to build and inexpensive. They also have the ability to operate in high temperatures and pressures.

The flow stream enters the body of the separator tangentially through the inlet at the top (see Figure 6.1). The mixture of solids and fluid or vapor begins...

Not correctly cited

Looks like you got some parts from http://www.eng-forum.com/recycling/Plastic_Reyclin g_Cyclone.htm

0 out of 1 people found this comment useful.