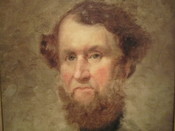

Cyrus Hall McCormick (1809-1884) On the cold day and dreary day of February 15, 1809, Cyrus Hall McCormick was born to in the county of Rockbridge County in Virginia. He was born to his parents Robert and Jane McCormick; the two owned a family farm there in Virginia. His dad had a variety of skills: blacksmith, inventor, and farmer. His dad was in the process of making a reaper, which was never completed so Cyrus took up the job of finishing it for him.

In 1831 he had completed the first grain reaper. He had demonstrated it but it never went on to be marketed and sold until 1837 when he updated it and licensed out manufacturers and out of his steal company. At first there was not a good response in his area because it tired out the horses that would pull the reaper along the steep hillsides. Then in 1844 he went west where it would meet more sells and more sells.

In the West the cost of labor was so high that it would be better for the reaper to be there because it did not take that much labor to run it. The conditions there in the West were more favorable then that in the East. The land was flatter and the crops were not as thick.

Around 1847 he went back up to Chicago and started his own companies that would manufacture all the grain reapers that would be sold. In the late 1840s and the early 1850s he introduced a new reaper that was more economical than the first. This had more benefits than the others.

He finally married in 1858 when he was 49. Then on May 13, 1884 he died leaving his business to his son who kept the business going until it merged in 1902 forming the International Harvester Company.

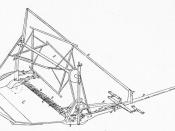

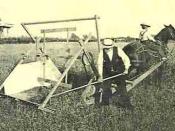

The grain reaper was a machine that was pulled by a team of horses. I would cut the stem of the ripened wheat and then it would fall on to a conveyor belt then move to the edge where it would form a small bundle. A person would take a few of the stems and wrap them around the bundle and then tie it. The bundles were then moved into a big stack that would be picked up by 2 people on the ground with pitchforks going behind a wheat trailer. Then after that they would take it to the threshing machine and tossed in by 2 people separating the grains from the wheat heads and stems. You can still see the machine work everyday in Fairview, OK at the annual Threshing Bee.