Shielded Metal Arc Welding (SMAW)

Operation

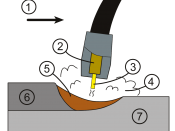

One reason for the wide acceptance of the SMAW process is the simplicity of the operation of the machine and the necessary equipment. Welding is performed with the heat of an electric arc that is maintained between the end of a coated metal electrode and the work piece (See Figure 1). The heat produced by the arc melts the base metal, the electrode core rod, and the coating. As the molten metal droplets are transferred across the arc and into the molten weld puddle, they are shielded from the atmosphere by the gases produced from the decomposition of the flux coating. The molten slag floats to the top of the weld puddle where it protects the weld metal from the atmosphere during solidification.

Application

The Shielded Metal Arc Welding process can be utilised for the joining of steels, stainless steels, cast irons, and also certain nonferrous alloys.

It is rarely used for aluminum and its alloys, copper alloys, or titanium. More commonly used for out of position work and work that may occur in windy conditions such as the outdoors. The gaseous shroud created by the flux in order to protect the molten pool of metal is not as easily blown away in the wind as occurs in the GMAW process.

Equipment

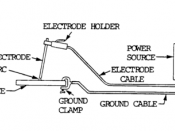

The equipment for SMAW consists of the following items. (See Figure 2)

1. Power source (15 Amps should be used rather than domestic 12A power sockets)

2. Electrode holder

3. Ground clamp

4. Welding cables

5. Accessory equipment including chipping hammer and wire brush)

6. Protective equipment such as helmet (see Figure 3)

Advantages

The main advantage of SMAW is that the initial investment in equipment is low - with Stick welding you receive more amps per dollar compared to MIG welding.