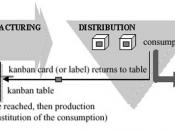

Just-In-Time is the practice that requires the consumption of resources at the last possible moment relative to production for customer demand. This requires the elimination of all waste - all the non-value added activities that take place in the total manufacturing, distribution and purchasing processes.

The emphasis of a J-I-T program is on minimization of warehousing costs/reduced inventories, frequent shipments and short delivery lead times. Management must adopt a method of inventory control which features high inventory turns and low safety stocks. This is just the opposite of a conventional system where inventory is stockpiled.

The introduction of Just-In-Time manufacturing has provided many benefits including a base for an increase in annual turnover, halving of inventory, a cut in lead time from weeks to days, a drop in labor turnover, and a reduction of waste and re-work levels. It also increases the number of skills per employee. J-I-T incorporates a better company image, improved morale and good housekeeping.

Just-In-Time minimizes quality problems that can result when parts sit around for a long time. It requires supplier quality assurance and to implement a zero defects quality program. Errors leading to defective items must be eliminated, since there are no buffers of excess parts. A quality control manager at the source must be implemented to give workers the personal responsibility for the quality of the work they do and the authority to stop production when something goes wrong.

J-I-T also reduces quality problems when workers and managers continually are assessing processes, methods and materials for their value contribution to the firm's product line. Quality can be accomplished by a reduction of inventory levels to cause problems to surface in the organization; reduce purchase order quantities and production lot sizes. Once problems are detected, they can be solved. The result is a smoother...

Incomplete analysis

over all I like the content of the article however in order for the analysis to be complete there should have been some comments about the other end of the spectrum i.e. what is wirn with JIT. This articles only emphasizes the good and gives reader no idea about the bad , hence is skewed.

0 out of 0 people found this comment useful.