Acrylic Fiber Characteristics o Outstanding wickability & quick drying to move moisture from body surface o Flexible aesthetics for wool-like, cotton-like, or blended appearance o Easily washed, retains shape o Resistant to moths, oil, and chemicals o Dyeable to bright shades with excellent fastness o Superior resistance to sunlight degradation Some Major Acrylic Fiber Uses ÃÂ÷ Apparel: Sweaters, socks, fleece wear, circular knit apparel, sportswear and childrens wear ÃÂ÷ Home Furnishings: Blankets, area rugs, upholstery, pile; luggage, awnings, outdoor furniture ÃÂ÷ Other Uses: Craft yarns, sail cover cloth, wipe cloths ÃÂ÷ Industrial Uses: Asbestos replacement; concrete and stucco reinforcement Lyocell Fiber Characteristics o Soft, strong, absorbent o Fibrillated during wet processing to produce special textures o Excellent wet strength o Wrinkle resistant o Very versatile fabric dyable to vibrant colors, with a variety of effects and textures.

o Can be hand washable o Simulates silk, suede, or leather touch o Good drapability o Biodegradable Some Major Lyocell Fiber Uses ÃÂ÷ Apparel: Dresses, slacks, coats, jeans First U.S.

Commercial Nylon Fiber Production: 1939, DuPont Company Current U.S. Nylon Fiber Producers: BASF Corporation; DuPont Company; Honeywell; Solutia Inc.; Universal Fiber Systems, L.L.C.; Wellman, Inc.

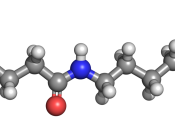

Federal Trade Commission Definition for Nylon Fiber: A manufactured fiber in which the fiber forming substance is a long-chain synthetic polyamide in which less than 85% of the amide-linkages are attached directly (-CO-NH-) to two aromatic rings. (Complete FTC Fiber Rules here.) Basic Principles of Nylon Fiber Production "ÃÂ The term nylon refers to a family of polymers called linear polyamides. There are two common methods of making nylon for fiber applications. In one approach, molecules with an acid (COOH) group on each end are reacted with molecules containing amine (NH2) groups on each end. The resulting nylon is named on the basis of the number of carbon atoms separating the two acid groups and the two amines. Thus nylon 6,6 which is widely used for fibers is made from adipic acid and hexamethylene diamine. The two compounds form a salt, known as nylon salt, an exact 1:1 ratio of acid to base. This salt is then dried and heated under vacuum to eliminate water and form the polymer.

In another approach, a compound containing an amine at one end and an acid at the other is polymerized to form a chain with repeating units of (-NH-[CH2]n-CO-)x. If n=5, the nylon is referred to as nylon 6, another common form of this polymer. The commercial production of nylon 6 begins with caprolactam uses a ring-opening polymerization.

In both cases the polyamide is melt spun and drawn after cooling to give the desired properties for each intended use. Production of nylon industrial and carpet fibers begins with an aqueous solution of monomers and proceeds continuously through polymerization, spinning, drawing, or draw-texturing.

Nylon Characteristics o Exceptionally strong o Elastic o Abrasion resistant o Lustrous o Easy to wash o Resistant to damage from oil and many chemicals o Can be precolored or dyed in wide range of colors o Resilient o Low in moisture absorbency o Filament yarns provide smooth, soft, long-lasting fabrics o Spun yarns lend fabrics light weight and warmth Some Major Nylon Fiber Uses ÃÂ÷ Apparel: Blouses, dresses, foundation garments, hosiery, lingerie, underwear, raincoats, ski apparel, windbreakers, swimwear, and cycle wear ÃÂ÷ Home Furnishings: Bedspreads, carpets, curtains, upholstery ÃÂ÷ Industrial and Other Uses: Tire cord, hoses, conveyer and seat belts, parachutes, racket strings, ropes and nets, sleeping bags, tarpaulins, tents, thread, monofilament fishing line, dental floss Olefin Fiber Characteristics o Able to give good bulk and cover o Abrasion resistant o Colorfast o Quick drying o Low static o Resistant to deterioration from chemicals, mildew, perspiration, rot and weather o Thermally bondable o Stain and soil resistant o Strong o Sunlight resistant o Dry hand; wicks body moisture from the skin o Very comfortable o Very lightweight (olefin fibers have the lowest specific gravity of all fibers) Some Major Olefin Fiber Uses ÃÂ÷ Apparel: Activewear and sportswear; socks; thermal underwear; lining fabrics ÃÂ÷ Automotive: Interior fabrics used in or on kick panel, package shelf, seat construction, truck liners, load decks, etc.

ÃÂ÷ Home Furnishings: Indoor and outdoor carpets; carpet backing; upholstery and wall coverings; furniture and bedding construction fabrics ÃÂ÷ Industrial: Carpets; disposable, durable nonwoven fabrics; ropes; filter fabrics; bagging; geotextiles Polyester Fiber Characteristics o Strong o Resistant to stretching and shrinking o Resistant to most chemicals o Quick drying o Crisp and resilient when wet or dry o Wrinkle resistant o Mildew resistant o Abrasion resistant o Retains heat-set pleats and crease o Easily washed Some Major Polyester Fiber Uses ÃÂ÷ Apparel: Every form of clothing ÃÂ÷ Home Furnishings: Carpets, curtains, draperies, sheets and pillow cases, wall coverings, and upholstery ÃÂ÷ Other Uses: hoses, power belting, ropes and nets, thread, tire cord, auto upholstery, sails, floppy disk liners, and fiberfill for various products including pillows and furinture Rayon Fiber Characteristics o Highly absorbent o Soft and comfortable o Easy to dye o Drapes well The drawing process applied in spinning may be adjusted to produce rayon fibers of extra strength and reduced elongation. Such fibers are designated as high tenacity rayons, which have about twice the strength and two-thirds of the stretch of regular rayon. An intermediate grade, known as medium tenacity rayon, is also made. Its strength and stretch characteristics fall midway between those of high tenacity and regular rayon.

Some Major Rayon Fiber Uses ÃÂ÷ Apparel: Accessories, blouses, dresses, jackets, lingerie, linings, millinery, slacks, sportshirts, sportswear, suits, ties, work clothes ÃÂ÷ Home Furnishings: Bedspreads, blankets, curtains, draperies, sheets, slipcovers, tablecloths, upholstery ÃÂ÷ Industrial Uses: Industrial products, medical surgical products, nonwoven products, tire cord ÃÂ÷ Other Uses: Feminine hygiene products Spandex Fiber Characteristics o Can be stretched repeatedly and still recover to very near its original length and shape o Generally, can be stretched more than 500% without breaking o Stronger, more durable and higher retractive force than rubber o Lightweight, soft, smooth, supple o In garments, provides a combination of comfort and fit, prevents bagging and sagging o Heat-settable "àfacilitates transforming puckered fabrics into flat fabrics, or flat fabrics into permanent rounded shapes o Dyeable o Resistant to deterioration by body oils, perspiration, lotions or detergents o Abrasion resistant o When fabrics containing spandex are sewn, the needle causes little or no damage from "needle cutting"àcompared to the older types of elastic materials o Available in fiber diameters ranging from 10 denier to 2500 denier o Available in clear and opaque lusters Some Major Spandex Fiber Uses o Garments where comfort and fit are desired: hosiery, swimsuits, aerobic/exercise wear, ski pants, golf jackets, disposable diaper, waist bands, bra straps and bra side panels o Compression garments: surgical hose, support hose, bicycle pants, foundation garments o Shaped garments: bra cups