SynopsisThe objective of this experiment is to measure the force required to stretch a specimen material until it breaks using modern tensile testing machine.

In tensile test experiment, after knowing the measurement (thickness and width) of 4 different specimens, place one of the specimens to the grips. Start the test program, when the specimen breaks, test results and Load against Extension graph are obtained in the program.

Through this experiment we can find the breaking load, maximum load, tensile strength and tensile modulus of different type of thermoplastic materials. Specimen with highest tensile strength is the strongest, which required larger amount of load to break the specimen. In this experiment, the result will show us that Purpose Polystyrene (GPPS) has the highest tensile strength and therefore breaking load is the largest among all other specimens.

Introduction to Tensile testTensile test work out by pulling the sample from both end and measure the force required to pull the specimen until it fractures along with how much the sample elongate before breaking.

This test is being conducted to test the ability of a material to resist breaking under tensile stress. It is being preformed for several reasons. Tensile strength is used in selecting materials for structural applications. Tensile properties are usually included in material specifications to ensure quality and often are measured during development of new materials, so that different materials can be compared.

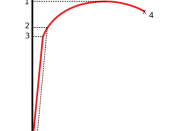

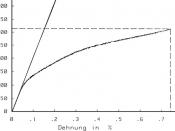

Theory by on tensile testTensile properties indicate how the material will react to forces being applied to it. A tensile test is probably the most basic mechanical test we can perform on material where a specimen is load in the tensile testing machine, measuring the applied load and the extension of the specimen over some distance. From tensile test, we can get a graph of load against extension, which than we can convert into a stress against strain curve. Stress is obtained by dividing the load by constant value, which is the area of the specimen. And strain is obtained by dividing the extension by another constant value, which is the original length of the specimen. The load-extension curve will have the same shape as the stress-strain curve since both stress and strain are obtain by dividing with a constant value. From the stress-strain curve, we can find out the tensile modulus at elastic region by dividing stress by strain. And from the load-extension curve, we can get tensile strength and yield strength by dividing the breaking load and maximum load by area respectively. However, we can only obtain yield strength for ductile material as a ductile material yields before failure, whilst a brittle material does not exhibit yielding.

Procedure1.4 specimen are selected which is the General Purpose Polystyrene (GPPS), High Impact Polystyrene (HIPS), High Density Polyethylene (HDPE) and Polypropylene (PP).

2.After thickness and width is measured and recorded, the particular program for tensile testing of thermoplastic is loaded.

3.A specimen is placed to the correct type of grips and with the capacity of the load cell checked, the test program may start. The tensile testing machine pulls the sample from both ends and measures the force required to pull the specimen apart and how much the sample stretches before breaking. From this, we will obtain load-extension curve.

4.The Experiment is repeated 2 more times with the same specimen to get a total of 3 readings and have their average.

5.The whole procedure is repeated with other specimens.

Results and CalculationsGeneral Purpose Polystyrene (GPPS) at Room TemperatureNo.Width, mmThickness, mmBreaking Load, NTensile Strength, N/mm2Tensile Modulus, N/mm2113.433.261523.534.7991680.8213.433.261793.440.9611676.1313.433.241646.837.8741580.0Mean37.8781645.633High Impact Poltstyrene (HIPS) at Room TemperatureNo.Width, mmThickness, mmBreaking Load, NMaximum Load, NTensile Strength, N/mm2Tensile Modulus, N/mm2Yield Strength, N/mm2113.533.34874.661199.719.3551075.926.548213.533.35870.711211.319.2101079.526.725313.503.33871.161183.119.3791066.026.318Mean19.3146671073.826.53033High Density Polyethylene (HDPE) at Room TemperatureNo.Width, mmThickness, mmBreaking Load, NMaximum Load, NTensile Strength, N/mm2Tensile Modulus, N/mm2Yield Strength, N/mm2112.672.95268.58945.217.1858569.7625.289212.713.25340.05953.988.2320525.9123.095312.72.7294.50954.088.5886620.9627.824Mean8.0021333572.2125.40267Polypropylene (PP) at Room TemperatureNo.Width, mmThickness, mmBreaking Load, NMaximum Load, NTensile Strength, N/mm2Tensile Modulus, N/mm2Yield Strength, N/mm2113.183.10864.241165.421.152591.7328.523213.093.16732.871202.117.717578.0229.060313.263.19802.331187.618.968579.5928.076Mean19.279583.113328.553â¢HOW DO WE CALCULATE TENSILE STRENGTH?We will use the result of GPPS no. 3 to showing our working.

Tensile Strength= Area=13.43mm x 3.24mm= 37.846 N/mm2â¢HOW DO WE CALCULATE YIELD STRENGTH?HIPS no.3 from the result table is used as an example.

Yield Strength= Area= 13.50mm x 3.33mm= 26.317 N/mm2DiscussionQuestions:1.Does PS exhibit yielding? What is the Yield strength of HIPS?Generally PS does not exhibit yielding for instances, General Purpose Polystyrene (GPPS) does not exhibit yielding however, High Impact Polystyrene (HIPS) exhibit yielding. The average Yield strength of HIPS is 26.530N/mm22.What is present in HIPS that is not present in PS that makes HIPS yields?Rubber (polybutadene) particle is present in HIPS that is not present in PS that makes it yields.

3.Compare the mean tensile strength, yield strength and tensile modulus of the four thermoplastics.

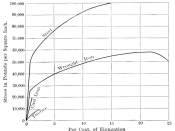

SpecimenTensile Strength, N/mm2Tensile Modulus, N/mm2Yield Strength, N/mm2GPPS37.8781645.6-HIPS19.3151073.826.530HDPE8.002572.2125.403PP19.279583.1128.553From the table, it shows that among all four specimens, GPPS requires the largest force per unit area to make it break as it has the highest tensile strength while HDPE requires the smallest force per unit area to fracture as it has the lowest tensile strength.

In comparison, GPPS has the highest tensile modulus and HDPE has the lowest among all four specimens. As tensile modulus is the ratio of stress to strain in elastic region, a high tensile modulus means the material is rigid due to the reason that more stress is required to produce a unit of strain. Therefore GPPS is the most rigid while HDPE is the least rigid among all the four specimens.

PP displays the highest yield strength while HDPE with the lowest yield strength. This means that PP has the highest strength of resistance to plastic deformation while HDPE has the lowest. GPPS does not have yield strength due the reason that GPPS is brittle and rigid as mention earlier.

4.Briefly describe in less than 100 words the "Tensile Test"Tensile Test is used widely to measure some of the key mechanical properties of plastics used in structural applications. It is the most basic, inexpensive and standardised type of mechanical test we can perform on materials. Simply by putting a specimen to the tensile testing machine, we could get the result of how the material will react to the force being applied to it almost immediately.

ConclusionFrom this experiment, we found that different polymer have different tensile strength, tensile modulus and yield strength, with GPPS having the highest tensile strength and tensile modulus, followed by HIPS, PP and HDPE having the lowest. We can conclude that polymer with higher tensile modulus usually exhibits low or no yield strength as high tensile modulus material is rigid. GPPS is the strongest as it withstand large amount of load before it break, however, it break almost immediately once the maximum load reaches. While HDPE require less amount load to break it, but exhibits yielding, takes longer time to break even when the maximum load has reach. With these points, we can conclude that the combination of high tensile strength and high yield strength will leads to material of high toughness. Tensile properties are important for us to determine which material is suitable for a specific application to ensure quality. All in all, tensile test is important, simple and relatively inexpensive way to determine tensile properties.

Reference:1.http://www.asminternational.org/pdf/spotlights/5106_01.pdf2.http://www.ndt-ed.org/EducationResources/CommunityCollege/Materials/Mechanical/Tensile.htm