Microelectromechanical Systems (MEMS)

A Microelectromechanical system (MEMS) is a miniature device formed by combining mechanical parts and electronic circuits, typically on a semiconductor chip, with dimensions from tens to a few hundred micrometers (millionths of a meter). Some examples of MEMS devices include accelerometers, robots, locks, micro-mirrors, optical scanners, fluid pumps and transducers. As technology continues to improve and continues to be applied to MEMS, an increasing number of novel applications begin to emerge. MEMS are a "fabrication approach that conveys the advantages of miniaturization, multiple components, and microelectronics to the design and construction of integrated electromechanical systems" (Vittorio). Due to ubiquitous nature of MEMS devices, they are without a doubt a multi-billion dollar market with interest from industry and the federal government.

The term "micromachining" (The use of standard semiconductor process technologies in combination with specially developed processes to fabricate miniature mechanical devices and components on silicon and other materials) came into use around 1982 to describe the fabrication of micromechanical parts for silicon micro-sensors.

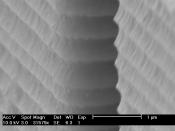

These parts were made by etching the silicon substrate away, until the desired geometries are remaining. The term "MEMS" was coined during a series of separate workshops on micro-dynamics held in 1987 where techniques for integrated fabrication of mechanisms on silicon were demonstrated (Vittorio). Many different techniques for accomplishing this were created, including such techniques as isotropic etching and anti-isotropic etching, which form the foundation for the manufacturing technologies; bulk micromachining, surface and high aspect ratio (HAR) silicon machining.

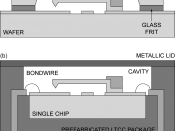

Bulk micromachining refers to a set of processes that enable the three-dimensional sculpting of single-crystal silicon to make small structures that serve as components of micro-sensors. More specifically, it is a fabrication technique, which involves etching away at a silicon wafer until only the desired parts remain. Usually the wafer used is photo patterned which...