MRP IN THE THIRD WORLD

Summary

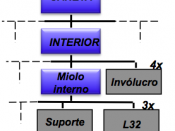

Since 1970 there has been a crusade for the MRP (Material Requirements Planning). Different approaches to the design of MRP II-based systems that have functioned as companywide integrators of the material planning process have continued to flourish, both in the literature and on the shop floor. It was quickly recognized that a MPS (Master Production Schedule) must drive the material plans generated by MRP. In its most simplistic form, MPS specified the configuration of a matched set of parts that MRP would subsequently plan at lower levels of the production system. MPS therefore managed independent demands on the production system while MRP managed dependent demands through component inventory records and product structure explosions. The article first refers to different manufacturing environments as first, second, and third world; then focuses on the difficulties posed by the particular manufacturing environment of "the third world".

The First World

In this world, MPS items are finished end items made-to-stock. The MPS is stated in terms of forecast item demand converted to a series of production lots via time-phased order points. Customer orders are entered by a final item number, and the master-schedule-planned production lots are generated by actual or projected order point trips. Here the master schedule is stated in terms of finished products. In the first world of MRP many different purchased components and raw materials are obtained, finished, and assembled into a final finished item. The MPS-MRP system works very naturally under this environment because of the low ratio of the MPS planned parts to the MRP planned parts.

The Second World

This is the world of custom make-to-order items where the MPS can be stated in terms of basic models and options. A custom product such as a machine tool is...

Very good

very good essay, very clear and to the point..well detailed..thank u

0 out of 0 people found this comment useful.