Objective:

1. To determine the percent recovery from recrytalisation

2. To determine the melting point of the crystals formed

3. To purify a solid by recrystalisation.

Apparatus:

- Erlenmeyer flask

- Filter paper

- Short-stemmed funnel

- Buchner funnel

Material:

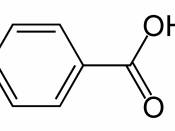

- Benzoic acid

- Charcoal

- Boiling chips

Procedure:

About 2.0g of crude benzoic acid was weighed into a 250mL Erlenmeyer flask.

100 - 200mL of water with boiling chips were heated to boiling in a beaker on a hot plate.

An Erlenmeyer flask with a little water and boiling chips in it was heated. A short-stemmed funnel was rested at its neck and a filter paper was fluted to fit the funnel.

A few boiling chips were added to the benzoic acid. Hot water was added to it until the benzoic acid dissolve.

The flask was kept on the hot plate once the hot water was added to keep it hot.

Decolorizing charcoal was added because colored impurities were present.

The hot solution was filtered through the fluted filter paper into the heated flask.

The original flask and the filter paper were rinsed with a little hot water.

The solution of benzoic acid was removed from the hot plate and allowed to cool.

After 15 minutes, the flask was cooled in an ice bath.

The crystals formed were collected by suction filtration using Buchner funnel.

A wet filter paper was fit to the Buchner funnel before pouring the crystals in.

The crystals on the wet filter paper were transferred onto a fresh piece of filter paper and were allowed to air-dry.

Once the crystals are dried, the weight was taken and recorded.

Observations & Results:

Original weight of benzoic acid = 1.95g

Weight of filter paper = 0.54g

Weight of filter paper + benzoic acid crystal = 2.32g

Weight of benzoic acid

compound recovered after recrystallization = 2.32 - 0.54

= 1.78g

weight of compound recovered

Percent Recovery = ---------------------------------------- x 100 %

original weight of compound

1.78g

= -------- x 100 %

1.95g

= 91.28 %

Melting point of crystal = 125oC - 126oC

Discussion:

We started off the experiment by weighing 1.95g of benzoic acid which was taken as the original weight that is 1.95g in this experiment. And then, seven steps were followed in order to complete the recrystalization process and finally the weight of the recovered compound was taken which is, 1.78g, to calculate the percent recovery.

The first step out of the seven steps mentioned earlier is to identify a good solvent. In this experiment, water was chosen as the solvent because benzoic acid is relatively insoluble in water at room temperature but much more soluble in water at higher temperature. This difference in solubility at hot versus cold temperatures is essential for the recrystallization process. Other than that, water is a good solvent because it does not react with benzoic acid. At the same time, water is also a good solvent for the benzoic acid impurities at both high and low temperatures.

The second step is to dissolve the sample in the minimum volume of hot water to get a good yield of a saturated solution in an Erlenmeyer flask. Erlenmeyer flasks were chosen over beakers for recrystallization because the conical shape of an Erlenmeyer flask decreases the amount of water lost to evaporation during heating, prevents the formation of a crust around the sides of the glass, and makes it easier to swirl the hot solution while dissolving the benzoic acid solid without splashing it out of the flask. More water was added gradually until all of the solid just dissolved. This was done to ensure that the solution was saturated to a degree that it would produce crystalline material once cooled. A few boiling chips were added into the Erlenmayer flask containing benzoic acid compound. Boiling chips are small, insoluble, porous stones made of calcium carbonate or silicon carbide. These stones have pores inside which provide cavities both to trap air and to provide spaces where bubbles of solvent vapor can form. When a boiling chip is heated in a solvent, it releases tiny bubbles. These bubbles ensure even boiling and prevent bumping and boiling over and loss of the solution.

We did not add decolorizing charcoal into the solution as there were no traces of coloured materia

The hot saturated solution was then filtered into another Erlenmayer flask with a little hot water in it, through a filter funnel with a fluted filter paper fitted on its wall. We were asked to use a stemless funnel to avoid the crystals to form and stuck in the stem of the funnel as soon as the Erlenmayer flask is removed from the hotplate, but as we were not provided with a stemless funnel, this problem was solved by having the second Erlenmayer flask with the funnel put on the hotplate during the hot filtration process to heat the funnel and prevent the solute from recrystallizing in the stem. A fluted filter paper was used to because it has an even and large surface area, allowing a much fast filtration.

Upon completing the hot filtration process, we continued by cooling the filtered solution. The filtered solution was left to cool undisturbed at room temperature to allow crystals to form. After several minutes, the Erlenmayer flask was put into an ice bath to allow for maximum recovery of material. The hot solution was not rapidly cool by placing the flask in an ice bath before it has cooled to room temperature because this will result in a rapid precipitation of the solid in an impure form because of trapped impurities.

Once the benzoic acid was judged to have completely precipitated from the solution, it is separated from the remaining solution (also called the mother liquor) by suction filtration. The Erlenmeyer flask was rinsed with a small volume of cold water to remove any remaining crystals. Cold water was also added to the funnel and then the

crystals in the funnel were washed to remove any remaining mother liquor and dissolved impurities. The water used had to be as cold as possible to prevent the crystal from dissolving as this would cause the loss of recovered benzoic acid. The crystals were left for a few minutes and allow air to pass through the crystals to dry them. After that, the crystals were transferred and were spread on a dry filter paper to allow the last traces of water to evaporate.

The percent of recovery in this experiment was 91.28%. Thus, the approximate impurity is about 8.72% of the benzoic acid compound. There might also be other factors causing the percent of recovery to be less than 100%. It could be because of some solute had crystallized on the fluted filter paper during the hot filtration process. Other than that, some crystal might also had been lost when the crystal were transferred to a dry filter paper to allow it to dry.

The range of the melting points of the crystals of benzoic acid was 125 úC to 126 úC. The range was determined when the bubbles were first seen to the time when the compound melted completely into a transparent liquid. This crystals obtained were impure. The reason why the crystals obtained were impure might be because of impurities as it lowers the melting point. It takes less energy to disrupt crystal lattice when impurities are present making the melting point to be lower and broader. The more pure the crystals of a compound are, the closer the sample is to the maximum melting point of the compound and the narrower is the temperature range over which melting occurs.

Conclusion:

o The percent of recovery of benzoic acid in this experiment was 91.28%.

o The melting point of the crystals was in the range of 125oC - 126oC.

o The crystals were impure.

References:

o http://designerdrugs.com/pte/12.162.180.114/dcd/chemistry/equipment/recrystallization.html

o http://www.xula.edu/chemistry/organic/Notes/07Recr.pdf

o http://orgchem.colorado.edu/hndbksupport/dist/boilchip.html

o http://en.wikipedia.org/wiki/Recrystallization

o http://www.chem.arizona.edu/courses/chem243/recrystallization.html

o http://www.miracosta.cc.ca.us/home/dlr/210exp1b.htm