Introduction

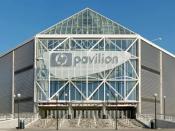

Riordan Manufacturing Incorporated is an industry leader in plastic injection molding. State-of-the art design capabilities allow creation of innovative plastic designs that have earned international acclaim. Attention to detail, extreme precision and enthusiastic quality controls are hallmarks of Riordan Manufacturing. With facilities in San Jose, California, Albany, Georgia, Pontiac, Michigan and Hangzhou, China, we have the capacity to fulfill the unique needs of any organization. Riordan Industries, a Fortune 1000 enterprise, own Riordan Manufacturing.

"Riordan Manufacturing has requested recommendations that will improve their inventory and/or their manufacturing processes. The SDLC process will be used starting with recommendation through the implementation phases. We will also explore several options to automate the inventory process to a just in time system in an effort to reduce the amount of working capitol needed for inventory." (Apollo, 2006)

Background of Situation

The slow consolidation of the operational processes of two divisions with different non-compatible operation software's has become a financial threat to Riordan Manufacturing.

The current situation of the Financial and Accounting systems between the division's in Michigan and Georgia has required increased labor to process information. Each division lacks modern technology that is needed to run a highly efficient corporation. Government documents and consolidated reports are delivered late due to the delay in the reporting systems.

Expected Results

Expectation is a complete consolidation. Meaning that integration of the two systems to reduce the chaos, this currently occurs between the Michigan and Georgia locations. We expect a reduction of the soft costs that are associated with the inefficient operating system that are currently employed at Riordan through integration and upgrading of the two systems. Riordan's technology needs to be upgraded to a level that will last a minimum of five years without becoming obsolete. Upgrading the system will make the integration run smoother. Documents...