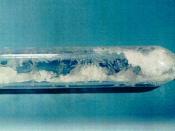

Uranium hexafluoride (UF6) is a compound used in the uranium enrichment process to produce fuel for nuclear reactors and nuclear weapons. It consists one atom of uranium combined with six atoms of fluorine. Natural uranium is 99.284% Uranium 238-isotope, with Uranium 235-isotope only constituting about 0.711% of its weight. However for uranium to be used as a nuclear fuel, the proportion of the U-235 isotope has to be much high. In order to increase the proportion, natural uranium or "yellowcake" must first be converted into gaseous uranium hexafluoride, then go through a process called enrichment.

Enriching uranium is a difficult and energy intensive process. This is because the two isotopes have identical chemical properties, and are very similar in weight: U-235 is only 1.26% lighter thanU-238. It requires a centrifuge that can spin at 1,500 revolutions per second, whereas washing machines operate at only about 12 to 25 revolutions per second.

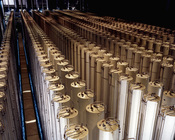

Several production methods have been used to enrich uranium and one of it is the zippe-type centrifuge (image to the right). It was developed in the Soviet Union by a team of 60 German scientists, led by Gernot Zippe, working in detention, captured after World War II. The device has a hollow, cylindrical rotor, which the gaseous uranium hexafluoride is contained in. A pulsating magnetic field at the bottom of the rotor, similar to that used in an electric motor, is able to spin it quickly enough that the U-238 is thrown towards the edge. The lighter U-235 collects in the centre. The bottom of the cylinder is heated, producing convection currents that move the U-238 down and U-235 up, where scoops collect it. To reduce the amount of energy required, the rotor is spun in a vacuum to reduce friction. A magnetic bearing holds the top of the rotor steady, and the only physical contact is the needle-like bearing that the rotor sits on. Also the rotor is usually built longer to increase their speed of rotation and efficiency. Comparing to other enrichment methods, zippe-type centrifuge is much cheaper and can be used in relative secrecy. This makes it ideal for covert nuclear weapons programs and possibly increases the risk of nuclear proliferation. Centrifuge cascades also have much less material held up in the machine at any time, unlike gaseous diffusion plants.

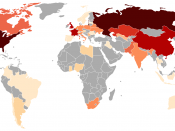

Low-enriched uranium (LEU), Highly enriched uranium (HEU) and Depleted uranium (DU) are three types of products of uranium enrichment. Low-enriched uranium is used in commercial light water reactors (LWR), the most prevalent power reactors in the world, uranium is enriched to 3 to 5% U-235. Fresh low-enriched uranium used in research reactors is usually enriched 12% to 19.75% U-235.

Highly enriched uranium is used as the fissile uranium in nuclear weapons containing 85% or more of U-235 known as weapon(s)-grade, though for a crude, inefficient weapon 20% is sufficient (called weapon(s) -usable). A high proportion of U-235 is necessary because the presence of too much of the U-238 isotope inhibits the runaway nuclear chain reaction that is responsible for the weapon's power. The critical mass for 85% of highly enriched uranium is about 50 kilograms, which at normal density would be a sphere less than 11 inches in diameter. HEU is also used in fast neutron reactors as well as in naval reactors, where it contains at least 50% U-235, but typically does not exceed 90%. However for criticality experiments, enrichment of uranium to over 97% has been accomplished.

Depleted uranium is the remaining U-238 isotope after enrichment. Since only a small proportion of the original uranium contains Uranium-235, large amounts of waste result from the enrichment process in the form of uranium hexafluoride. It is considerably less radioactive than even natural uranium (around 60% as radioactive as naturally occurring uranium), though still extremely dense and toxic. It is useful for armour- penetrating weapons like staballoys, and other applications requiring very dense metals. However at the present time, only 5% of it is put to any use; the rest remains in storage at the enrichment facilities. It is estimated that the global stockpile of depleted uranium is 1.3 to 1.5 million tonnes, much of which is stored as uranium hexafluoride. Depleted uranium hexafluoride presents environmental, health, and safety risks because of its chemical instability. When uranium hexafluoride is exposed to moist air, it reacts with the water in the air to produce UO2F2 (uranyl fluoride) and HF (hydrogen fluoride) both of which are highly soluble and toxic. Storage cylinders must be regularly inspected for signs of corrosion and leaks. There have been several accidents involving uranium hexafluoride in the United States. The U.S. government has been converting depleted uranium hexafluoride to solid uranium oxides for disposal. Such disposal of the entire depleted uranium hexafluoride inventory could cost anywhere from $15 million to $450 million.

Bibliography:Uranium hexafluoridehttp://en.wikipedia.org/wiki/Uranium_hexafluorideDepleted UF6 Management Informationhttp://web.ead.anl.gov/uranium/index.cfmEnriched Uraniumhttp://en.wikipedia.org/wiki/Uranium_enrichment#Separative_work_unitUranium Enrichment by Jim Falk and Roger Bodmanhttp://www.energyscience.org.au/FS07%20Enrichment.pdfZippe-type centrifugehttp://en.wikipedia.org/wiki/Zippe-type_centrifugeNuclear Engineering Internationalhttp://db.bbc.co.uk/radio4/science/zippetype.shtmlThe Zippe Typehttp://www.npec-web.org/Essays/20041022-GilinskyEtAl-LWR.pdf#page=35