Enzyme used to make PLA: Ralstonia eutropha

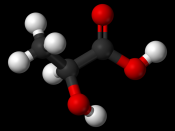

Polylactic acid is produced through the fermentation of cornstarch or glucose into lactic acid using the bacteria Ralstonia eutropha. The lactic acid is then converted to Polylactic acid using traditional polymerization processes.

Evaluation of the use of PLA

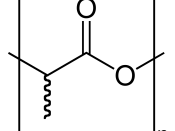

Currently Polylactic acid is used in a number of biomedical applications, such as sutures, tissue engineering and absorbable wound closure products. Currently PLA is more expensive then other plastics, but in the near future it should become cheaper and more widely used due to its many properties and advantages.Polylactic acid exhibits good durability, flexibility, high gloss, clarity and excellent tensile strength. Furthermore it is non-static which makes it ideal for shipping sensitive electronics. PLA has potential application in many areas such as textiles, agriculture and sanitation. It can be used to make disposable garments, plant mats, tree nets, food packaging, nappies and disposable tableware.

One of the main advantages of PLA is that it is renewable and minimizes environmental waste, as it may be fully biodegraded by micro-organisms under appropriate conditions into carbon dioxide and water. This greatly reduces the environmental impacts of plastic use and manufacture as it reduces the dependence on non-renewable fossil fuels.

However, there are still energy concerns and social impacts which need to be addressed in order to make PLA a viable material. Efficiency is a major concern in the production of PLA and bioplastics in general. Currently, fossil fuel is still used as an energy source during the production process. Consequently this has raised questions regarding how much fossil fuel is actually saved by manufacturing bioplastics. Only a few processes have emerged that actually use less energy in the production process. Therefore, researchers are still working on refining the processes used in order to make bioplastics viable...