Bioplastics are a new generation of biodegradable plastics made from synthetic biopolymers; its components are derived entirely or almost entirely from renewable raw materials. Biopolymers are an environmental friendly alternative to petroleum-based polymers (traditional plastics).

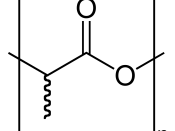

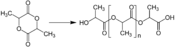

Polylactide aliphatic copolymer is a synthetic biopolymer made from a mixture of lactide and aliphatic polyester. A copolymer is made from 2 or more different monomers. The monomer lactide is made from lactic acid (see fig2), which is a methyl-substituted glycolic acid that can be produced by the fermentation of corn, cheese, whey and other agricultural sources. Lactic acid is the biomass feedstock (organic matter produced by plants that can be used as a renewable fuel) of bioplastics (see fig1).

Aliphatic polyester is a biopolymer made from condensation polymerisation of glycol and aliphatic dicarboxylic acids. Both components can be obtained from renewable resources (e.g. glycol from glycerol by fermentation). Aliphatic polyesters have properties similar to those of polyethylene and polypropylene.

They are odourless and can be used for trash bags, diapers, and cosmetics. Aliphatic polyesters are biodegradable but lack good thermal and mechanical properties.

Polylactide aliphatic copolymer (CPLA) is made by copolymerising lactide with aliphatic polyester (see fig3). CPLA is a thermoplastic and unlike aliphatic polyesters, it can be either a hard plastic (similar to polystyrene) or a soft flexible one (similar to polypropylene) depending on the amount of aliphatic polyester present in the mixture. Also CPLA has improved thermal properties, stable to heat up to 200 ðC. CPLA can be processed into useful products with most conventional plastic processes. (eg blow moulding, injection moulding, extrusion, vacuum forming, fibre spinning)

CPLA is transparent and odourless, possible applications of CPLA will include compost bags, cushioning materials, food wrapping materials, fishing nets, etc. Although CPLA has a high molecular weight and high melting point, it begins...