During recent times, many organizations have recognized tremendous progress in effectiveness and efficiency by adopting a pull strategy that establishes the pace of production at the rate of customer demand. Additional advantages accrue when a similar strategy is applied to the supply chain, as is seen with the adoption of just-in-time (JIT) approaches. However, such approaches can have disastrous effects when there is strategic misalignment between organizations. It was introduce a new conception of supply-chain integration based upon backwards pulling of strategic initiatives through the supply network in order to provision the creation and maintenance of valuable inter-organizational relationships.

It is recognized the monumental advantage held by a business that can

produce a product at the lowest unit cost in its industry, while at the same time, creating such differentiation that its product commands a premium price in the market. Obviously, such an organization is the envy of its competitors in terms of profitability, which is the position of manufacturers who have mastered pull production (Johnson and Bröms, 2000).

Fundamentally, pull production achieves low cost by completing production at the rate of customer demand, and as a result of the discipline required for such pacing of production, commonly generates differentiation in the form of improved quality and reduced cycle times (Womack, Jones and Roos, 1999; Womack and Jones, 1999; Johnson and Bröms, 2000). Some exemplars of pull production even display remarkable flexibility.

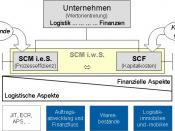

Just In Time (JIT) approaches to Supply Management (SCM) represent an effort to gain the same advantages from the supply chain. By removing inventories, and improving the systemic linkages between organizations, leading-edge organizations have brought their suppliers on board in efforts to promote greater effectiveness and efficiency. A combination of pull production within the organization and JIT supply operations are central to the lean revolution documented by Womack...