Introduction:

Manual metal arc welding was first invented in Russia in 1888. It involved a bare metal rod with no flux coating to give a protective gas shield. The development of coated electrodes did not occur until the early 1900s when the Kjellberg process was invented in Sweden and the Quasi-arc method was invented in the UK. But the coated electrodes used these days were slow to be adopted because of their high cost. But because the need for strong welds grew, manual metal arc and coated electrodes became a unit; Stainless steel, inconel, nickel and cast iron electrodes are also commonly used, as are surfacing type electrodes for the building up of wear resistant surfaces.

Mma is widely used in the fabricating industries for the construction and repair of plain carbon and low alloy steels. the equipment is of initial low cost, and the process is flexible and safe to use.

Good ventilation and protective clothing is essential

Manual metal arc welding is known by many names depending on the country and the region; some of them are shown in the following table:

NameDescriptionCountry

MMAManual Metal Arc

STICKManual Metal Arc

ELECTRIC ARCManual Metal Arc

SMAWShielded Metal Arc Welding

Description of the Process

Consists of an AC/DC arc burning between a consumable electrode, when an arc is struck between the metal rod (electrode) and the work piece, both the rod and work piece surface melt to form a weld pool, Instant melting of the flux coating on the rod will form gas and slag which protects the weld pool from the surrounding atmosphere. The slag will solidify and cool and must be chipped off the weld bead once the weld run is complete (or before the next weld pass is deposited).

Equipment:

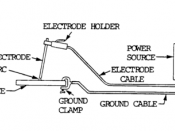

The basic equipment consists of:-

Power source: Requires...