YEAR 11 CHEMISTRY

14

MATERIALS FOR THE

FUTURE - KEVLAR MRS EZARD

TATSUYA SHIIHARA

[TATSUYA SHIIHARA] Term 2 Semester 1 2014

1 | P a g e

Materials of the Future: Kevlar

In this day and age, advances in technology have led to the ability to stare knowingly up at space and

down to the smallest atoms. As a result, many efficient and effective materials have been discovered

and developed, known commonly as

polymers. Polymers are comprised of

monomers, individual molecules, which are

then attached in sequences of chains that

create the polymer. (Encyclopedia Britannica,

2014) With physical properties much better

than other materials, such as higher melting

points, strength and malleability, polymers

can either be naturally occurring (Starch,

cellulose, etc.) or synthetic (Teflon, Kevlar,

etc.). Now applied to nearly all aspects of

everyday life, they can exist in simple

objects such as gloves cards and piping, and also in much more sophisticated apparatuses such as

bulletproof vests.

Chemically known as poly-para-phenylene terephthalamide, Kevlar, one of the foremost polymers

used in the world today, is a cutting-edge, highly effective polymer that has been utilised since the

early 1970's, and is particularly renowned for its

ability to withstand bullet impacts. (Chemistry

in the Military, 2012) First conceived in 1965 by

Stephanie Kwolek, this synthetic polymer uses

much of its intermolecular structure for its

exceptional physical properties, and is

particularly used in the personal protection field,

with Kevlar being the foremost of materials in

bullet-proof vests. ( Marlow Ropes, 2013)

[TATSUYA SHIIHARA] Term 2 Semester 1 2014

2 | P a g e

Intermolecular forces are the forces that are between combined molecules that hold everything

together, and there are three types of these forces. These are; London dispersion forces, dipole -

dipole forces and hydrogen bonding. London dispersion forces, al so referred as Van Der Waal's

forces, are weak, instantaneous weak attraction forces that occur between the slightly positive area

of a polar molecule and the slightly negative area of another molecule. This occurs between all

molecules. Dipole-dipole forces exist between two polar molecules as a magnetic force, due to the

various electronegativity's of molecules. (See Appendix A for further information on

electronegativity) They are stronger than dispersion forces, yet weaker than hydrogen bonds. The

strongest bonding of the three, Hydrogen bonding is the result of attraction between a hydrogen

atom and a specific, highly electronegative particle and element. (Virtual Science Fair, 2008)

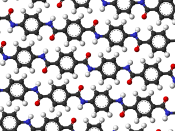

As can be seen in figure 1, the fabrication process of Kevlar is a condensation reaction, where

monomers join together with a small by-product. The 2 monomers in this case are 1, 4-phenyl-

diamine (para-phenylenediamine) and terephthaloyl chloride, with the by-product being

Hydrochloric Acid. (Chemistry in the Military, 2012) The 2 monomers are held together by dipole-

dipole forces. In order to make Kevlar, the substance that was produced by the condensation

reaction (called the intermediate) must be drawn. (Virtual Science Fair, 2008) This is simply

stretching the product at a certain temperature to strengthen the final product. As drawing the

Kevlar at specific temperatures affects the strength of the final material, it can be inferred that

different heat levels alter resulting Kevlar filaments. Stretching the mould at 400oC, Kevlar-29, the

most common Kevlar used today can be created, whereas in contrast the strongest strand, Kevlar-49,

needs a significantly greater temperature. (Du Pont, 2012) After the Kevlar is drawn, it is spun by

being forced through a spinneret to produce the strands. It is then washed, neutralised and dried

before being wound into coils that are easier for buyers to use, rather than sheets of the material.

(Du Pont, 2012)

Figure 1: Reaction of 1,4-phenylene-diamine (para-phenylenediamine) with

terephthaloyl chloride resulting in Kevlar with a by-product of Hydrochloric Acid.

(Chemistry in the Military, 2012)

[TATSUYA SHIIHARA] Term 2 Semester 1 2014

3 | P a g e

Undoubtedly, Kevlar's superior quality comes from its molecular structure and bonding. Crystalline

properties occur as an inevitable result of the creation of Kevlar, ensuring that the molecules are

straight and ordered. However, a polymer that is crystalline tends to be very strong but does not

have a high malleability factor. (Virtual Science Fair, 2008) Kevlar tends to balance both the factors,

hence resulting in a manipulable material that also has maximised strength. Kevlar has a trans-

conformation ability through its benzene rings and the way each monomer is bonded to the others.

( Putting the pieces together - Microworlds, 2010) As can be seen in Figure 2, this does not allow cis-

conformation, or bends in the molecules, and results in a fully drawn-out fibre as shown in Figure 3,

allowing the polymer to withhold its outstanding level of strength. Hence, Kevlar has an uncommon

property of high tensile strength-to-weight ratio), meaning that it is in reality 5 times stronger than

steel on an equal weight basis. (Du Pont, 2012) (See Appendix A on "tensile strength-to-weight")

Figure 4: Intermolecular forces in Kevlar's

structure (Virtual Science Fair, 2008)

London Dispersion Forces

continuously occurring

Hydrogen bonding

between Kevlar

filaments

Dipole-dipole bonding between

Oxygen, Nitrogen and Carbon

Benzene Rings (See Appendix A for

further information)

Figure 2: Why cis-conformation doesn't form in Kevlar.

(Virtual Science Fair, 2008) Figure 3: Trans-conformation in Kevlar.

(Virtual Science Fair, 2008)

Cis-conformation cannot

occur as the structure is too

tight, with no space for all the

atoms.

A trans-conformation pattern

allows space for all atoms,

with everything stretched out,

and is the form Kevlar takes.

[TATSUYA SHIIHARA] Term 2 Semester 1 2014

4 | P a g e

As can be seen in Figure 4, whilst dispersion forces are helping to constantly hold the fibres together,

although they are very weak and can be easily broken, a huge amount of energy comes from the

hydrogen bonding that holds the strands of Kevlar together. ( Marlow Ropes, 2013) This undeniably

is one of the main reasons that Kevlar has exceptional strength. As a result, all of these

intermolecular properties give Kevlar countless benefits over other polymers. Kevlar can retain the

same amount of strength until 300oC, before starting to decompose at an exceptionally high 500oC.

On the contrary, it can also retain its strength at up to 196oC, with no indication of embrittlement. As

well as this, other than a few powerful acids, virtually all solvents are unsuccessful in degrading

Kevlar. (Virtual Science Fair, 2008)

When asked about the uses of Kevlar, most people tend to think of bulletproof vests and body

armour, yet unbeknownst to most, they are also commonly found as reinforcement in tires and

wheels, as boat hulls, tennis racquet frames, protective casings for fuel cells in aerospace industries,

extra strengthening for fibre-optic cables, various ropes and cables, hoses, helmets and protective

gear for many situations to name a few. (Chemistry in the Military, 2012) (Hamsn Corporation, 2011)

( Marlow Ropes, 2013) It is obvious that all of these applications come accordingly because of the

many intermolecular properties Kevlar exhibits, including the bonding forces, bonding pattern,

trans-conforming properties and balance of strength, crystallinity and flexibility.

[TATSUYA SHIIHARA] Term 2 Semester 1 2014

5 | P a g e

Comparison with another polymer: Zylon

Another polymer that also has a wide range of applications as Kevlar does, is Zylon. Used in areas

such as personal protection, high-altitude balloons, motorsports and yacht rigging, Zylon has a

structure that comprises of dipole-dipole forces that hold it together, as well as constant London

dispersion forces. (Technical F1 Dictionary, 2012) This can be seen in Figure 5.

The study below compares the energy absorption rate of Heavy Zylon, Light Zylon and Kevlar. As can

be seen in Graph 1, on one axis, there is the amount of energy absorbed in Joules and on the

other, the number of layers of the material there are.

Graph 1: Comparison of Kevlar and Heavy and Light Zylon's energy absorption rates

Dispersion forces constantly occurring

Dipole-dipole bonds hold the molecules

together

Benzene Rings

Figure 5: Intermolecular structure of Zylon

(Technical F1 Dictionary, 2012)

[TATSUYA SHIIHARA] Term 2 Semester 1 2014

6 | P a g e

Light Zylon and Heavy Zylon do not have different densities, but amount of denier, which indicates

the fineness of the material. Heavy Zylon is , whereas Light Zylon is only .

When compared, it can be seen from Graph 1 that Kevlar had the lowest absorption rate, with Light

Zylon being slightly higher, and Heavy Zylon clearly outstripping both. On average, Heavy Zylon's

absorbant rate was , whereas Light Zylon's is and Kevlar's was a

mere , as can be deduced from Graph 1.

From Graph 1, it can be seen that Heavy Zylon can absorb up to 3 times more energy than Kevlar

when they both have the same number of layers, making it a much better material in terms of

effectiveness in energy absorption terms. However, it has been revealed that with Zylon, both heavy

and light types tend to degrade rapidly during usage, which makes it very impractical for bulletproof

vests. (Pereira & Revilock, 2008) (Chemistry in the Military, 2012) It can be inferred that this

property is due to the absence of hydrogen bonds holding the polymer together. Only having dipole-

dipole and dispersion forces, Zylon's components obviously can be separated much easier then

Kevlar's as there is less energy holding them together. This is seen in the fact that Zylon is known to

degrade in seawater, ultraviolet and visible light rays and friction. (Pereira & Revilock, 2008) Kevlar is

also known to degrade in UV, however this wall is overcome by the usage of a cover. (Chemistry in

the Military, 2012)

Unlike Kevlar, Zylon is produced by carbon nanotubes, being spun into a fibre. (Technical F1

Dictionary, 2012) (See Appendix A for further information on Carbon Nanotubes) Sacrificing the

malleability of the polymer, this process ensures high strength and therefore a high energy

absorption rate, but also forces the material to degrade at a much faster rate than other polymers.

Hence, Zylon's exceptional strength does majorly not come from the intermolecular forces, but

mostly from as a result of how it was created. (Technical F1 Dictionary, 2012)

With the capability of being reused without any major effects on its energy absorption, Kevlar is

indisputably the better-quality material, and this is obviously why it is currently the most utilised

polymer in the personal-protection field, as well as protective environments such as apparel, covers

and machinery. ( Putting the pieces together - Microworlds, 2010) Its chemical configuration and the

intermolecular bonding that hold it together help to produce a high-strength material that can be

used effectively and efficiently.

The use of Kevlar has most definitely not only transformed our way of thinking by showing us a

hopeful future with nanotechnology, but also has helped our various systems to be more efficient

and effective throughout the world. Without the introduction of Kevlar in the body-armour field, it is

almost certain that many lives would have been lost to this point. The necessary and advantageous

properties that Kevlar possesses for today and the future, both intermolecular and physical, make

Kevlar a highly desirable polymer, and hence it is encouraged to be adopted by industries and

societies worldwide that haven't already taken advantage of this magnificent polymer.

[TATSUYA SHIIHARA] Term 2 Semester 1 2014

7 | P a g e

Appendix A

Term Description

Electronegativity On the periodic table, Fluorine has the strongest electronegativity, and generally, the further away from there, the less electronegativity present. (Dr Nicole Ezard)

Tensile weight-to-strength ratio The maximum stress a material can endure before failure in tension. (Carbon Fiber Tube Shop, 2013)

Benzene Rings A hexagonal arrangement (ring) that consists of 6 Carbon atoms with alternating single and double bonds between them. Each Carbon atom is bonded to a hydrogen atom. (The Free Dictionary , 2010)

Carbon Nanotubes Composed of Carbon atoms linked in hexagonal shapes, each Carbon is covalently linked to three other carbon atoms. (UnderstandingNano.com, 2014)

[TATSUYA SHIIHARA] Term 2 Semester 1 2014

8 | P a g e

Works Cited Virtual Science Fair. (2008). Retrieved May 31st, 2014, from Kevlar:

http://www.odec.ca/projects/2004/clar4c0/public_html/en/fabrication.html

Putting the pieces together - Microworlds. (2010). Retrieved May 24th, 2014, from What Makes

Kevlar So Strong?: http://www2.lbl.gov/MicroWorlds/Kevlar/KevlarPutting.html

The Free Dictionary . (2010). Retrieved June 1st, 2014, from Benzene Rings:

http://www.thefreedictionary.com/benzene+ring

Hamsn Corporation. (2011). Retrieved May 18th, 2014, from Kevlar - High Performance Fibre:

http://www.hamsn.com/blog/kevlar-high-performance-fibre/

Chemistry in the Military. (2012). Retrieved May 22nd, 2014, from Kevlar:

http://advchemorange1.blogspot.com.au/2012/11/kevlar-by-max.html

Du Pont. (2012). Retrieved May 28th, 2014, from KEVLAR® BRAND:

http://www.dupont.com/products-and-services/fabrics-fibers-

nonwovens/fibers/brands/kevlar.view-all.usesapplication.html

Technical F1 Dictionary. (2012). Retrieved May 31st, 2014, from Zylon: http://www.formula1-

dictionary.net/zylon.html

Marlow Ropes. (2013). Retrieved May 26th, 2014, from Physical Properties:

http://www.marlowropes.com/technical/physical-properties.html

Carbon Fiber Tube Shop. (2013). Retrieved May 29th, 2014, from Tube Properties:

http://www.carbonfibertubeshop.com/tube%20properties.html

Encyclopedia Britannica. (2014). Retrieved May 23rd, 2014, from Kevlar:

http://www.britannica.com/EBchecked/topic/315780/Kevlar

UnderstandingNano.com. (2014). Retrieved May 28th, 2014, from What are Carbon Nanotubes?:

http://www.understandingnano.com/what-are-carbon-nanotubes.html

Johns, D., & Guess, J. (2006). Dipole-Dipole Interactions. Retrieved May 21st, 2014, from UC Davis

Chem Wiki:

http://chemwiki.ucdavis.edu/Physical_Chemistry/Quantum_Mechanics/Atomic_Theory/Inte

rmolecular_Forces/Dipole-Dipole_Interactions

Pereira, J. M., & Revilock, D. M. (2008). Ballistic Impact Response of Kevlar 49 and Zylon under

Conditions Representing Jet Engine Fan Containment.

Tatsuya Shiihara NEZ Materials of the Future Term 2 Semester 1 2014

Logbook

Logbook

Date Log

28/04/14 Decided on the use of Sodium Polyacrylate (main) and Cellulose (secondary) for the purpose of this assignment.

09/05/14 Intermolecular forces and electronegativity were found out online (Hydrogen, dipole- dipole, London Dispersion forces), in the Year 11 University Chemistry class (Mrs Natalie Hermon) and the Year 11 Chemistry Class (Dr Ezard)

11/05/14 Further research into Sodium Polyacrylate began.

12/05/14 Research on Sodium Polyacrylate continued.

13/05/14 Research on Sodium Polyacrylate continued.

15/05/14 Unfortunately, due to lack of information, Sodium Polyacrylate was discontinued as the main polymer and Kevlar and Zylon were discovered and decided upon.

16/05/14 Research on Kevlar began. - An introduction was written. - Uses of Kevlar were found. - Information regarding intermolecular forces was found and used.

21/05/14 The monomers that make up Kevlar were found. These were: 1, 4- phenyl-diamine (para-phenylenediamine) and terephthaloyl chloride. Condensation reaction also found.

23/05/14 Properties of Kevlar were found and used in the assignment.

26/05/14 Draft was handed in.

30/05/14 Feedback received.

31/05/14 Diagrams were found for both Kevlar and Zylon. More information about Zylon and Kevlar was found and utilised.

02/06/14 Research was completed for Zylon and Kevlar.

03/06/14 Assignment was concluded.

04/06/14 Assignment was submitted.

- 1. Title Page

- Assignment - Materials of the Future FINAL

- Logbook