Laser Welding:

Introduction:

Laser Beam Welding (LBW) is a modern welding process; it is a high energy beam process that continues to expand into modern industries and new applications because of its many advantages like deep weld penetration and minimizing heat inputs. The turn by the manufacturers to automate the welding processes has also caused to the expansion in using high technology like the use of laser and computers to improve the product quality through more accurate control of welding processes.

Major Difference:

The main difference between traditional electric arc welding processes is in the mode of energy transfer. Unlike electric arc energy transfer, laser energy absorption by a material is affected by many factors like the type of the laser, the incident power density and the base metal?s surface condition.

Two important factors to help characterizing laser welding are:

1- The energy transfer efficiency, which is the ratio of the heat observed by the workpiece to the incident laser energy.

2- The melting efficiency, which is the ratio of the heat to just melt the fusion zone to the heat observed by the workpiece.

The laser output is not electrical, does not require electrical continuity, is not influenced by magnetism, is not limited to electrically conductive materials, can contract with any material and its function doesn?t require a vacuum nor does it produce x-rays.

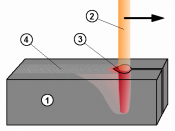

How it works:

The focal spot is targeted on the workpiece surface which will be welded. At the surface the large concentration of light energy is converted into thermal energy. The surface of the workpiece starts melting and progresses through it by surface conductance. For welding, the beam energy is maintained below the vaporization temperature of the workpiece material, because hole drilling or cutting vaporization is required.

Because the penetration of the workpiece depends on...