The advent of the internal combustion engine mobilized the world. Since its invention in the early 1800s, cars, trucks, airplanes, even boats now harness the power of ignited fuel to travel infinitely faster than ever previously thought possible. However the most commonly used engine type, the four-stroke, is not without its problems. The four stroke engine runs hot by nature, and requires a cooling system. The added weight from a radiator hurts fuel efficiency, and therefore costs more money. The four-stroke is also responsible in large part for global warming due to its high carbon monoxide emissions. These problems seem unavoidable, but modern engineers have solved them both in the form of the six stroke engine. Although not yet in every day application, there are several different kinds of six-stroke prototypes sporting impressive test results. The most promising of these designs however, appears to be Bruce CrowerÃÂs design which uses steam to generate a second power stroke.

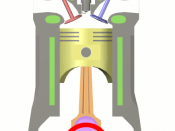

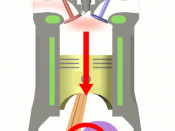

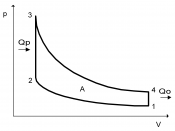

Normally after the power stroke in a normal four-stroke cycle the immense heat from the explosion is dealt with by a radiator. This isnÃÂt only inefficient because of the excess weight of a cooling system, but since up to 70% of the energy created by the motor is heat energy, itÃÂs also counter-productive. Bruce Crower believes the key to a more efficient engine is to harness the wasted heat energy and convert it to extra kinetic energy. His six-stroke design does this by injecting water directly into the cylinder immediately after the exhaust valve closes on the fourth stroke. The water almost instantaneously vaporizes and expands ÃÂup to 1600% its liquid massÃÂ, slamming the piston downward for another power stroke. On the sixth stroke the rising piston expels the steam, and the cycle repeats. The water is not only used to create a second power stroke however, but it also cools the cylinder head, eliminating the need for an external cooling system. That means far better fuel economy and much less environmentally harmful exhaust.

The use of water for a secondary fuel essentially gives the engine a free power stroke for every cycle. This means that only half the primary fuel (gasoline, diesel, LPS, etc.,) is used to create the same amount of kinetic energy as would be used in a normal four-stroke engine. At this point in the engineÃÂs life it uses about the same amount of water as it does gasoline. The water also apparently does a fantastic job of cooling the engine. Mr. Crower has stated ÃÂItÃÂll run for an hour and you can literally put your hand on it. ItÃÂs warm, yeah, but itÃÂs not scorching hot.ÃÂ Eliminating the use of a radiator also relieves a lot of weight, meaning the engine doesnÃÂt need to work as hard. Tests on the single cylinder engine have shown up to a 40% decrease in primary fuel consumption. The other major benefit of the CrowerÃÂs six-stroke engine is reduced emissions. There is still the burnt air-fuel mixture of the first power stroke, but the second only yields steam as exhaust. This six-stroke model has shown in tests to reduce harmful emissions by up to 65%. The steam also seems to do a good job of cleaning the exhaust system. Crower speculates that steam cleaning the engine every cycle could also do away with the need for a catalytic converter, and further reduce the weight of the vehicle.

The Crower six-stroke, being quite new, still has some hurdles to overcome, but early tests have proved to be very promising. Eliminating excess weight from the cooling system, while cutting both fuel consumption and emissions is a huge leap in automotive technology. Its ability to use a much higher percentage of the total energy created makes the six-stroke the next logical place for the auto industry to go.

Bibliography:http://en.wikipedia.org/wiki/Six_stroke_enginehttp://www.autoweek.com/apps/pbcs.dll/article?AID=/20060227/FREE/302270007/1023/THISWEEKSISSUEhttp://www.sixstroke.com/